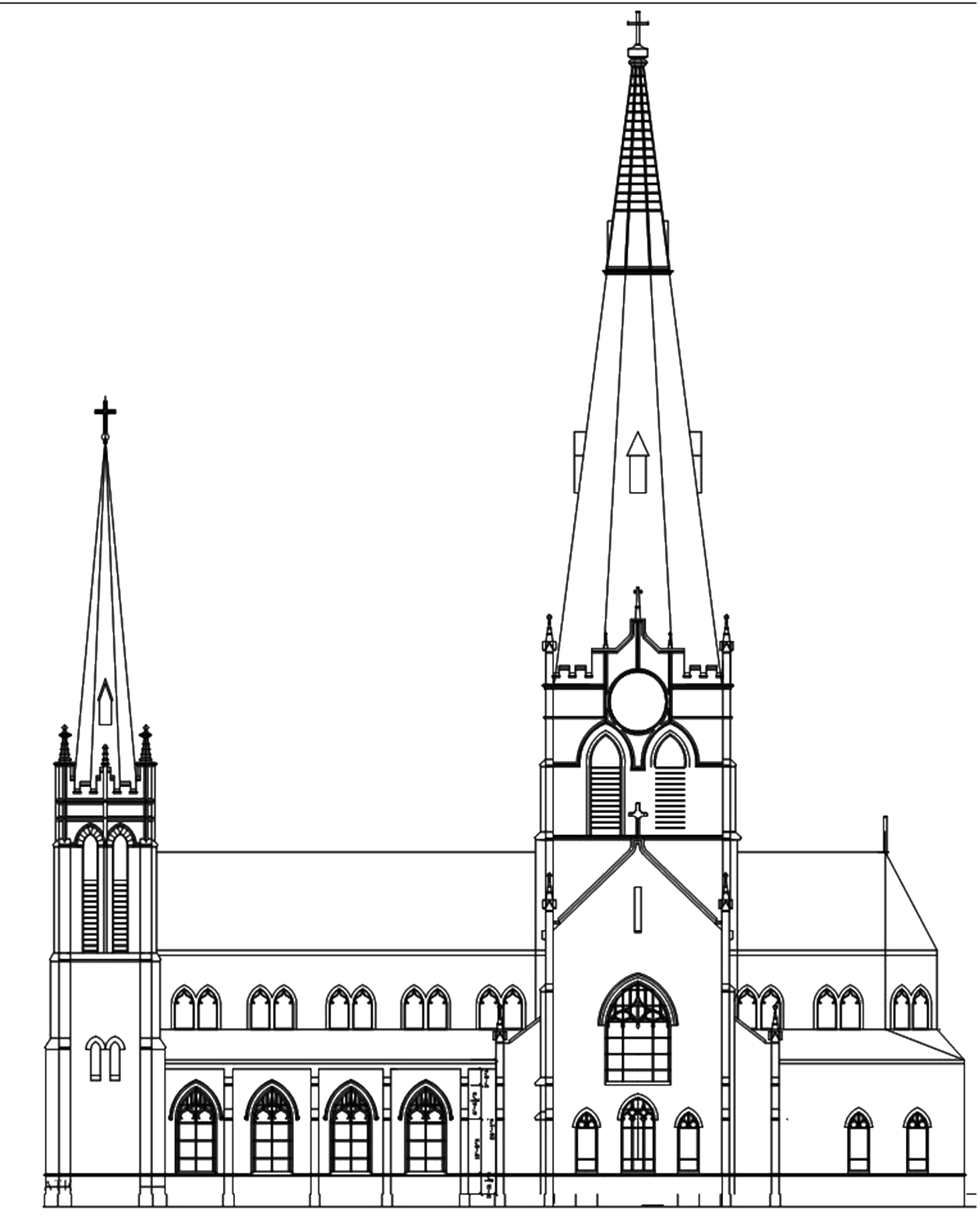

Holy Family’s Roof Project will see the fourth roof installed on the Cathedral in 111 years.

- The original 1914 roof was red slate tiles.

- The next roof, installed in 1959, was aluminum.

- A third roof installed in 2009 was copper-foil wrapped shingles.

The 2025 roof will be solid copper as shiny as a new penny.

Mr. Eddie Almarez, project manager, wants the roof to last for decades. He highlighted the four layers that make up a modern church roof.

Layer One: Metal Decking

Holy Family Cathedral has a steel superstructure. Made of Oklahoma red steel, the superstructure rises 251 feet from a concrete foundation. During the original construction in 1913 and 1914, roofers attached sheets of plywood to the superstructure and laid a tiled slate roof over it. In 1959, roofers attached a replacement roof directly to the existing plywood decking.

By 2009, the plywood decking reached the end of its useful life.

During that renovation, roofers removed the aluminum roof and the plywood decking. Section by section, they stripped the towers down to the steel superstructure and attached new metal decking.

That metal decking is in good shape and will be kept in place.

Layer Two: Wooden Decking

A layer of OSB, oriented strand board, is installed over the metal decking. OSB is an engineered wood product which is more durable than plywood and less expensive.

Layer Three: water-resistant, high temperature tolerant, self adhesive membrane

This membrane does all the hard work. It has to withstand very high temperatures: a copper roof on a hot day will transfer heat to this membrane. It must be water-resistant, keeping every drop of rain from getting inside the building.

This membrane does all the hard work. It has to withstand very high temperatures: a copper roof on a hot day will transfer heat to this membrane. It must be water-resistant, keeping every drop of rain from getting inside the building.

The material is self-adhesive. Roofers will peel off a backing layer, then stick the membrane to the wooden decking. They will use additional fasteners to ensure the membrane stays in place.

Our membrane is “Miami-Dade County Approved,” a mark of quality meaning that this material is suitable for applications where hurricane winds are common. It will work well during Oklahoma’s worst windstorms.

Roofers have already begun installing the membrane over the wooden decking.

Layer Four: Copper

The final layer will be solid copper shingles.

The Cathedral will get lots of attention as its new roof will gleam in the sun. Over several months, the color will mature into a chocolate brown. Many years from now, we will see a classic green patina.

Leave a Reply